Services

TUNRA Bulk Solids offers services for all industries dealing with bulk solid materials. Each year, we complete between 200 and 250 major industrial consultancy projects which cover the entire spectrum of applications related to bulk solids handling, transportation and storage. We are leaders in providing conceptual solutions to any bulk materials related task or problem that may occur in your plant, from fundamental characterisation to development of optimal designs, management processes and technical criteria. Our comprehensive laboratory test facilities and our highly qualified and committed team of engineers and consultants assist you to overcome existing handling problems and to plan new projects to ensure future trouble-free plant operation. Detailed information about the services offered by TBS can be viewed below either by Industry, Material Type or Handling Problem. For further information about a specific service or if you want to make an enquiry, please contact us directly or download our service brochures.-

Services By Handling Problems

DEM and Calibration Services

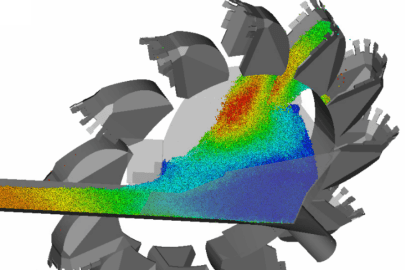

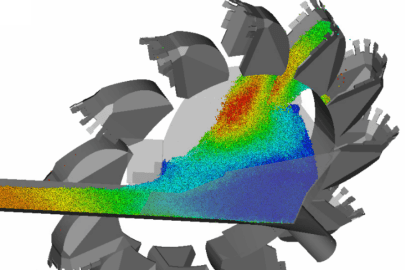

DEM and Calibration Services Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk […]

Wear and Attrition Testing

Any mechanical devices which involve the motion of bulk solids relative to surfaces will experience wear problems.

Wear in bulk handling equipment may result from impact or abrasion or, as is often the case, a combination of both. In addition, deterioration of metal surfaces can occur as a result of corrosion

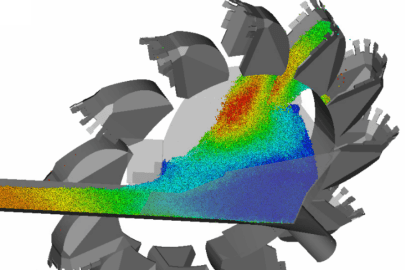

Transfer Chute Design

Transfer chutes are used in bulk handling systems to perform a variety of operations. For instance accelerating the bulk material from a slow moving belt or apron feeder onto a conveyor, or capturing and re-directing the flow of bulk material from one conveyor belt to another.

It is important that a chute is designed correctly to ensure the efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear. The importance is accentuated with a trend towards higher conveying speeds and ever increasing throughputs.

-

Services By Industry

DEM and Calibration Services

DEM and Calibration Services Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk […]

Wear and Attrition Testing

Any mechanical devices which involve the motion of bulk solids relative to surfaces will experience wear problems.

Wear in bulk handling equipment may result from impact or abrasion or, as is often the case, a combination of both. In addition, deterioration of metal surfaces can occur as a result of corrosion

Transfer Chute Design

Transfer chutes are used in bulk handling systems to perform a variety of operations. For instance accelerating the bulk material from a slow moving belt or apron feeder onto a conveyor, or capturing and re-directing the flow of bulk material from one conveyor belt to another.

It is important that a chute is designed correctly to ensure the efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear. The importance is accentuated with a trend towards higher conveying speeds and ever increasing throughputs.

-

Services By Material Type

DEM and Calibration Services

DEM and Calibration Services Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk […]

Wear and Attrition Testing

Any mechanical devices which involve the motion of bulk solids relative to surfaces will experience wear problems.

Wear in bulk handling equipment may result from impact or abrasion or, as is often the case, a combination of both. In addition, deterioration of metal surfaces can occur as a result of corrosion

Transfer Chute Design

Transfer chutes are used in bulk handling systems to perform a variety of operations. For instance accelerating the bulk material from a slow moving belt or apron feeder onto a conveyor, or capturing and re-directing the flow of bulk material from one conveyor belt to another.

It is important that a chute is designed correctly to ensure the efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear. The importance is accentuated with a trend towards higher conveying speeds and ever increasing throughputs.