Services

TUNRA Bulk Solids offers services for all industries dealing with bulk solid materials. Each year, we complete between 200 and 250 major industrial consultancy projects which cover the entire spectrum of applications related to bulk solids handling, transportation and storage. We are leaders in providing conceptual solutions to any bulk materials related task or problem that may occur in your plant, from fundamental characterisation to development of optimal designs, management processes and technical criteria. Our comprehensive laboratory test facilities and our highly qualified and committed team of engineers and consultants assist you to overcome existing handling problems and to plan new projects to ensure future trouble-free plant operation. Detailed information about the services offered by TBS can be viewed below either by Industry, Material Type or Handling Problem. For further information about a specific service or if you want to make an enquiry, please contact us directly or download our service brochures.-

Services By Handling Problems

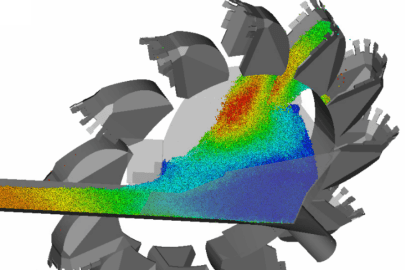

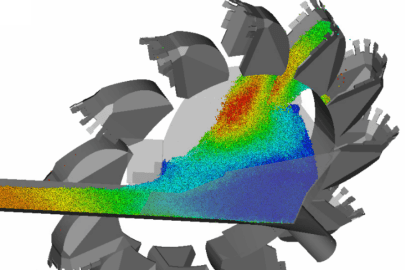

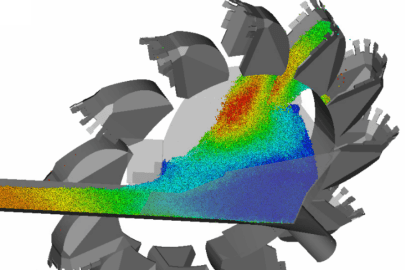

DEM and Calibration Services

DEM and Calibration Services Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk […]

Flow Properties Testing

Flow Properties Testing The design of handling and storage facilities requires knowledge of the behaviour and flow properties of the bulk solids under operating conditions. Conditions include loading and consolidation […]

Transfer Chute Design

Transfer chutes are used in bulk handling systems to perform a variety of operations. For instance accelerating the bulk material from a slow moving belt or apron feeder onto a conveyor, or capturing and re-directing the flow of bulk material from one conveyor belt to another.

It is important that a chute is designed correctly to ensure the efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear. The importance is accentuated with a trend towards higher conveying speeds and ever increasing throughputs.

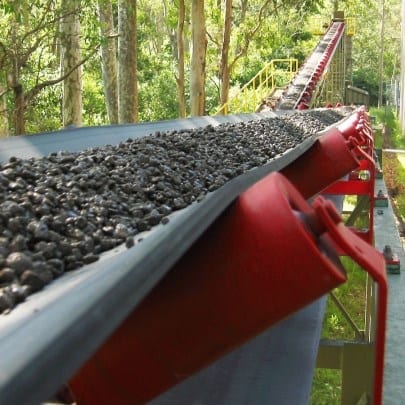

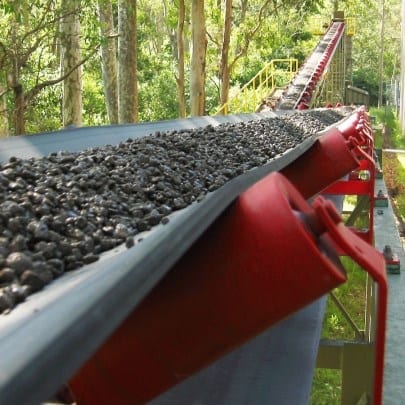

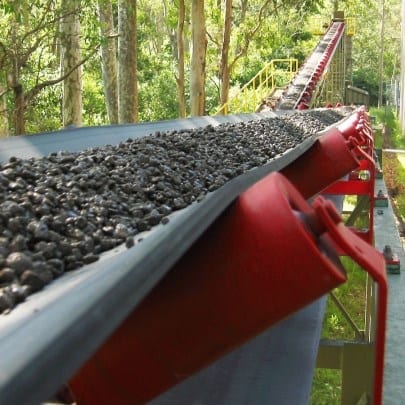

Conveyor Belt and Conveyor Accessories Testing

Belt conveyors play a major role in bulk materials handling operations. They combine versatility and reliability and, in view of their inherent simplicity of operation, they are suited to the conveying of a wide range of bulk materials.

They may be used effectively for the movement of bulk materials over both short and long distances.

In the latter case, the adaptability of their design and construction permits them to operate over undulating terrain.

Conveyor Idler Rolls

Conveyor idler rolls are integral components of belt conveying systems as they provide load support and control of the belt troughing profile.

Between 10-20 per cent of the overall rolling losses of a belt conveyor can be caused by the idler rolls of a belt conveyor system. Therefore, care must be taken to choose the best idler roll design for the respective purpose.

Bin and Hopper Design

Bins and hoppers are used for the storage of bulk materials during material handling processes. The hopper is the lower tapered section of a bin, which can also be found above feeders in gravity reclaim stockpiles.

Both must be designed for the actual bulk material being handled over the entire range of operating conditions including varying characteristics.

Testwork performed by TUNRA Bulk Solids (TBS) allows for the selection of optimum geometry of bins and hopper to ensure material flow initiation, reliable and predictable discharge and estimate of the loading on bin and hopper walls.

Hydraulic Conveying

Hydraulic transport of solids has occured since the beginning of time, the flow of fine solid particles in rivers being an easy everyday illustration. Advances in engineering and technology have transformed this natural phenomenon into commercially viable transport systems handling industrial minerals encompassing concentrates, ores and almost every type of tailing via slurry pipelines. TUNRA Bulk Solids offers a range of hydraulic conveying testing and evaluation services.

Transport Load-Out Systems

TUNRA Bulk Solids (TBS) offers services related to the design of transport load-out systems, including ship, train and truck to ensure reliable and predictable discharge and loading.

Contact our dedicated engineering team for troubleshooting, design audits of new and existing load-out systems and conceptual design expertise.

Feeder Optimisation and Design

Feeders control the gravity flow of bulk solids from storage, such as bins or stockpiles, to provide a uniform feedrate to the receiving belt conveyor.

It is vital that the type of feeder be chosen to suit the bulk material being handled and to provide the range of feed rates required. It is also important that feeders be used in conjunction with mass-flow hoppers to ensure both reliable flow and good control over the feeder loads and drive powers. Correct interfacing of feeders and hoppers is essential if performance objectives such uniform draw of material over the whole of the hopper outlet is to be achieved.

Stockpile Design

Gravity reclaim stockpiles are used for the short-term storage of bulk materials during material handling processes.

The design of associated storage and handling facilities requires knowledge of the bulk solid material characteristics over a range of different operating conditions.

TUNRA Bulk Solids (TBS) flow properties test work is required to be able to calculate the optimum stockpile and rathole geometry in order to maintain the required live capacity. Favourable concept design of the hopper and feeder interface is also important to ensure the best performance under all operating conditions.

Dust (Environmental) Testing

Understanding the dust/moisture relationship of a bulk material allows minimisation of water addition for dust suppression. This in turn assists in water conservation at mines and other handling facilities, as well as minimising the total moisture of the product

-

Services By Industry

DEM and Calibration Services

DEM and Calibration Services Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk […]

Flow Properties Testing

Flow Properties Testing The design of handling and storage facilities requires knowledge of the behaviour and flow properties of the bulk solids under operating conditions. Conditions include loading and consolidation […]

Transfer Chute Design

Transfer chutes are used in bulk handling systems to perform a variety of operations. For instance accelerating the bulk material from a slow moving belt or apron feeder onto a conveyor, or capturing and re-directing the flow of bulk material from one conveyor belt to another.

It is important that a chute is designed correctly to ensure the efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear. The importance is accentuated with a trend towards higher conveying speeds and ever increasing throughputs.

Conveyor Belt and Conveyor Accessories Testing

Belt conveyors play a major role in bulk materials handling operations. They combine versatility and reliability and, in view of their inherent simplicity of operation, they are suited to the conveying of a wide range of bulk materials.

They may be used effectively for the movement of bulk materials over both short and long distances.

In the latter case, the adaptability of their design and construction permits them to operate over undulating terrain.

Conveyor Idler Rolls

Conveyor idler rolls are integral components of belt conveying systems as they provide load support and control of the belt troughing profile.

Between 10-20 per cent of the overall rolling losses of a belt conveyor can be caused by the idler rolls of a belt conveyor system. Therefore, care must be taken to choose the best idler roll design for the respective purpose.

Bin and Hopper Design

Bins and hoppers are used for the storage of bulk materials during material handling processes. The hopper is the lower tapered section of a bin, which can also be found above feeders in gravity reclaim stockpiles.

Both must be designed for the actual bulk material being handled over the entire range of operating conditions including varying characteristics.

Testwork performed by TUNRA Bulk Solids (TBS) allows for the selection of optimum geometry of bins and hopper to ensure material flow initiation, reliable and predictable discharge and estimate of the loading on bin and hopper walls.

Hydraulic Conveying

Hydraulic transport of solids has occured since the beginning of time, the flow of fine solid particles in rivers being an easy everyday illustration. Advances in engineering and technology have transformed this natural phenomenon into commercially viable transport systems handling industrial minerals encompassing concentrates, ores and almost every type of tailing via slurry pipelines. TUNRA Bulk Solids offers a range of hydraulic conveying testing and evaluation services.

Transport Load-Out Systems

TUNRA Bulk Solids (TBS) offers services related to the design of transport load-out systems, including ship, train and truck to ensure reliable and predictable discharge and loading.

Contact our dedicated engineering team for troubleshooting, design audits of new and existing load-out systems and conceptual design expertise.

Feeder Optimisation and Design

Feeders control the gravity flow of bulk solids from storage, such as bins or stockpiles, to provide a uniform feedrate to the receiving belt conveyor.

It is vital that the type of feeder be chosen to suit the bulk material being handled and to provide the range of feed rates required. It is also important that feeders be used in conjunction with mass-flow hoppers to ensure both reliable flow and good control over the feeder loads and drive powers. Correct interfacing of feeders and hoppers is essential if performance objectives such uniform draw of material over the whole of the hopper outlet is to be achieved.

Stockpile Design

Gravity reclaim stockpiles are used for the short-term storage of bulk materials during material handling processes.

The design of associated storage and handling facilities requires knowledge of the bulk solid material characteristics over a range of different operating conditions.

TUNRA Bulk Solids (TBS) flow properties test work is required to be able to calculate the optimum stockpile and rathole geometry in order to maintain the required live capacity. Favourable concept design of the hopper and feeder interface is also important to ensure the best performance under all operating conditions.

Dust (Environmental) Testing

Understanding the dust/moisture relationship of a bulk material allows minimisation of water addition for dust suppression. This in turn assists in water conservation at mines and other handling facilities, as well as minimising the total moisture of the product

-

Services By Material Type

DEM and Calibration Services

DEM and Calibration Services Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk […]

Flow Properties Testing

Flow Properties Testing The design of handling and storage facilities requires knowledge of the behaviour and flow properties of the bulk solids under operating conditions. Conditions include loading and consolidation […]

Transfer Chute Design

Transfer chutes are used in bulk handling systems to perform a variety of operations. For instance accelerating the bulk material from a slow moving belt or apron feeder onto a conveyor, or capturing and re-directing the flow of bulk material from one conveyor belt to another.

It is important that a chute is designed correctly to ensure the efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear. The importance is accentuated with a trend towards higher conveying speeds and ever increasing throughputs.

Conveyor Belt and Conveyor Accessories Testing

Belt conveyors play a major role in bulk materials handling operations. They combine versatility and reliability and, in view of their inherent simplicity of operation, they are suited to the conveying of a wide range of bulk materials.

They may be used effectively for the movement of bulk materials over both short and long distances.

In the latter case, the adaptability of their design and construction permits them to operate over undulating terrain.

Conveyor Idler Rolls

Conveyor idler rolls are integral components of belt conveying systems as they provide load support and control of the belt troughing profile.

Between 10-20 per cent of the overall rolling losses of a belt conveyor can be caused by the idler rolls of a belt conveyor system. Therefore, care must be taken to choose the best idler roll design for the respective purpose.

Bin and Hopper Design

Bins and hoppers are used for the storage of bulk materials during material handling processes. The hopper is the lower tapered section of a bin, which can also be found above feeders in gravity reclaim stockpiles.

Both must be designed for the actual bulk material being handled over the entire range of operating conditions including varying characteristics.

Testwork performed by TUNRA Bulk Solids (TBS) allows for the selection of optimum geometry of bins and hopper to ensure material flow initiation, reliable and predictable discharge and estimate of the loading on bin and hopper walls.

Hydraulic Conveying

Hydraulic transport of solids has occured since the beginning of time, the flow of fine solid particles in rivers being an easy everyday illustration. Advances in engineering and technology have transformed this natural phenomenon into commercially viable transport systems handling industrial minerals encompassing concentrates, ores and almost every type of tailing via slurry pipelines. TUNRA Bulk Solids offers a range of hydraulic conveying testing and evaluation services.

Transport Load-Out Systems

TUNRA Bulk Solids (TBS) offers services related to the design of transport load-out systems, including ship, train and truck to ensure reliable and predictable discharge and loading.

Contact our dedicated engineering team for troubleshooting, design audits of new and existing load-out systems and conceptual design expertise.

Feeder Optimisation and Design

Feeders control the gravity flow of bulk solids from storage, such as bins or stockpiles, to provide a uniform feedrate to the receiving belt conveyor.

It is vital that the type of feeder be chosen to suit the bulk material being handled and to provide the range of feed rates required. It is also important that feeders be used in conjunction with mass-flow hoppers to ensure both reliable flow and good control over the feeder loads and drive powers. Correct interfacing of feeders and hoppers is essential if performance objectives such uniform draw of material over the whole of the hopper outlet is to be achieved.

Stockpile Design

Gravity reclaim stockpiles are used for the short-term storage of bulk materials during material handling processes.

The design of associated storage and handling facilities requires knowledge of the bulk solid material characteristics over a range of different operating conditions.

TUNRA Bulk Solids (TBS) flow properties test work is required to be able to calculate the optimum stockpile and rathole geometry in order to maintain the required live capacity. Favourable concept design of the hopper and feeder interface is also important to ensure the best performance under all operating conditions.

Dust (Environmental) Testing

Understanding the dust/moisture relationship of a bulk material allows minimisation of water addition for dust suppression. This in turn assists in water conservation at mines and other handling facilities, as well as minimising the total moisture of the product