Services List

-

Services By Handling Problems

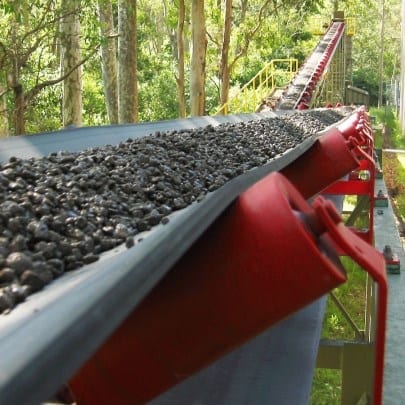

Conveyor Idler Rolls

Conveyor idler rolls are integral components of belt conveying systems as they provide load support and control of the belt troughing profile.

Between 10-20 per cent of the overall rolling losses of a belt conveyor can be caused by the idler rolls of a belt conveyor system. Therefore, care must be taken to choose the best idler roll design for the respective purpose.

The comprehensive facility of TUNRA Bulk Solids enables testing of conveyor idler rolls in reference to relevant International Standards and/or guidelines including the CEMA 6th Ed., DIN22112-3, ISO 5048 and SABS 1313-1.

Idler Roll Testing Services

Rolling Resistance of Conveyor Idler Rolls (Rim Drag)

A standard test involves centrally loading the conveyor idler roll with 25kg and operating it at a surface speed specified by the customer for four hours in each direction. The rim drag is the average of the two values measured after four hours of rotation in each direction. For new conveyor idler rolls, a run-in time of up to eight hours at operating speed is recommended before the rim drag test is conducted

Test temperature range: -10°C to +60°C

Idler Roll Dimensions: Length – up to 1250mm | Diameter – up to 194mm

.jpg?height=282&width=450)

Break-away Force

The break-away force is the force required to overcome the static friction inherent in the bearings and seal of a conveyor idler roll.

Testing for break-away force is usually conducted before and immediately after a rim drag test, but may also be carried out as a stand-alone test.

Maximum Indicated Slope (MIS)

The MIS is defined as the maximum indicated runout per 6° of idler roll rotation. It is determined by the radius variations around the circumference of the conveyor idler roll’s shell at 6° intervals at one position along its axis.

The largest difference between the consecutive measurements is specified as the MIS.

Total Indicator Runout (TIR)

The TIR is defined as the peak to peak variation in roll eccentricity and out of roundness. It is determined by the difference between the largest and smallest radius found around the circumference of a conveyor idler roll sheet at one position along its axis.

Operating Noise Output

The operating noise output refers to the noise generated by the interaction of a conveyor idler roll with a conveyor belt and provides a realistic representation of a conveyor idler roll’s in-service performance.

-

Services By Industry

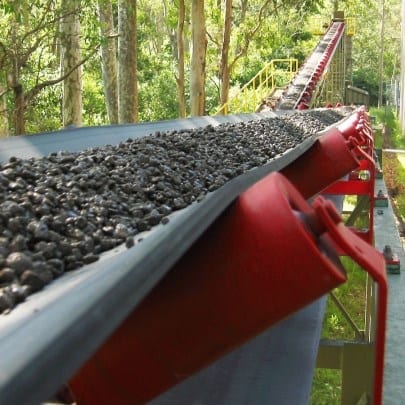

Conveyor Idler Rolls

Conveyor idler rolls are integral components of belt conveying systems as they provide load support and control of the belt troughing profile.

Between 10-20 per cent of the overall rolling losses of a belt conveyor can be caused by the idler rolls of a belt conveyor system. Therefore, care must be taken to choose the best idler roll design for the respective purpose.

The comprehensive facility of TUNRA Bulk Solids enables testing of conveyor idler rolls in reference to relevant International Standards and/or guidelines including the CEMA 6th Ed., DIN22112-3, ISO 5048 and SABS 1313-1.

Idler Roll Testing Services

Rolling Resistance of Conveyor Idler Rolls (Rim Drag)

A standard test involves centrally loading the conveyor idler roll with 25kg and operating it at a surface speed specified by the customer for four hours in each direction. The rim drag is the average of the two values measured after four hours of rotation in each direction. For new conveyor idler rolls, a run-in time of up to eight hours at operating speed is recommended before the rim drag test is conducted

Test temperature range: -10°C to +60°C

Idler Roll Dimensions: Length – up to 1250mm | Diameter – up to 194mm

.jpg?height=282&width=450)

Break-away Force

The break-away force is the force required to overcome the static friction inherent in the bearings and seal of a conveyor idler roll.

Testing for break-away force is usually conducted before and immediately after a rim drag test, but may also be carried out as a stand-alone test.

Maximum Indicated Slope (MIS)

The MIS is defined as the maximum indicated runout per 6° of idler roll rotation. It is determined by the radius variations around the circumference of the conveyor idler roll’s shell at 6° intervals at one position along its axis.

The largest difference between the consecutive measurements is specified as the MIS.

Total Indicator Runout (TIR)

The TIR is defined as the peak to peak variation in roll eccentricity and out of roundness. It is determined by the difference between the largest and smallest radius found around the circumference of a conveyor idler roll sheet at one position along its axis.

Operating Noise Output

The operating noise output refers to the noise generated by the interaction of a conveyor idler roll with a conveyor belt and provides a realistic representation of a conveyor idler roll’s in-service performance.

-

Services By Material Type

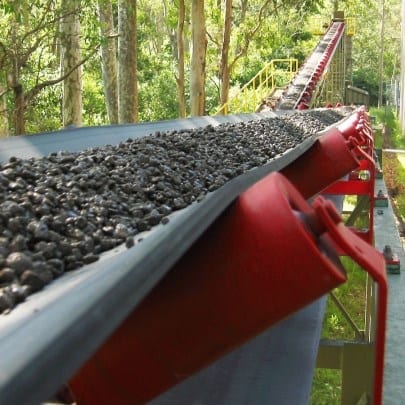

Conveyor Idler Rolls

Conveyor idler rolls are integral components of belt conveying systems as they provide load support and control of the belt troughing profile.

Between 10-20 per cent of the overall rolling losses of a belt conveyor can be caused by the idler rolls of a belt conveyor system. Therefore, care must be taken to choose the best idler roll design for the respective purpose.

The comprehensive facility of TUNRA Bulk Solids enables testing of conveyor idler rolls in reference to relevant International Standards and/or guidelines including the CEMA 6th Ed., DIN22112-3, ISO 5048 and SABS 1313-1.

Idler Roll Testing Services

Rolling Resistance of Conveyor Idler Rolls (Rim Drag)

A standard test involves centrally loading the conveyor idler roll with 25kg and operating it at a surface speed specified by the customer for four hours in each direction. The rim drag is the average of the two values measured after four hours of rotation in each direction. For new conveyor idler rolls, a run-in time of up to eight hours at operating speed is recommended before the rim drag test is conducted

Test temperature range: -10°C to +60°C

Idler Roll Dimensions: Length – up to 1250mm | Diameter – up to 194mm

.jpg?height=282&width=450)

Break-away Force

The break-away force is the force required to overcome the static friction inherent in the bearings and seal of a conveyor idler roll.

Testing for break-away force is usually conducted before and immediately after a rim drag test, but may also be carried out as a stand-alone test.

Maximum Indicated Slope (MIS)

The MIS is defined as the maximum indicated runout per 6° of idler roll rotation. It is determined by the radius variations around the circumference of the conveyor idler roll’s shell at 6° intervals at one position along its axis.

The largest difference between the consecutive measurements is specified as the MIS.

Total Indicator Runout (TIR)

The TIR is defined as the peak to peak variation in roll eccentricity and out of roundness. It is determined by the difference between the largest and smallest radius found around the circumference of a conveyor idler roll sheet at one position along its axis.

Operating Noise Output

The operating noise output refers to the noise generated by the interaction of a conveyor idler roll with a conveyor belt and provides a realistic representation of a conveyor idler roll’s in-service performance.