Services List

-

Services By Handling Problems

Transport Load-Out Systems

TUNRA Bulk Solids (TBS) offers services related to the design of transport load-out systems, including ship, train and truck to ensure reliable and predictable discharge and loading.

Contact our dedicated engineering team for troubleshooting, design audits of new and existing load-out systems and conceptual design expertise.

Train Load-Out Bins

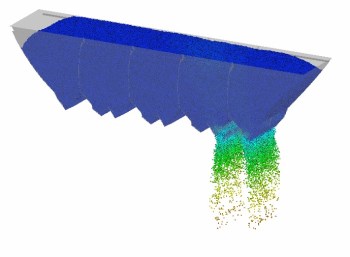

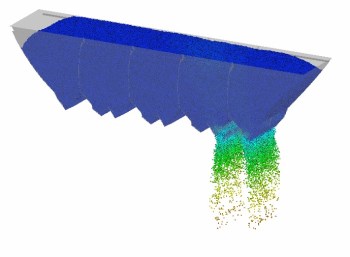

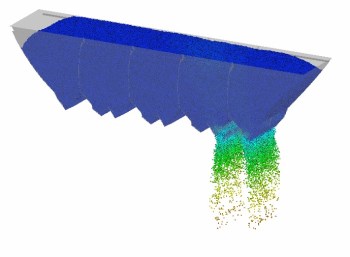

Train load-out (TLO) bins are generally large structures employing flood loading chutes to rapidly fill wagons underneath. When designing such structrues it is important to consider the dynamic loads associated as these can cause significant vibrations. Typically, the calculation of dynamic loads is based on traditional continuum mechanics calculations coupled with site data, however, more recently, with the advancement of computing power, Discrete Element Modelling (DEM) has also been used by TBS in the analyses of these systems. The unloading rate of TLO’s depends on factors such as gate opening time, corresponding outlet size, wagon speed and material properties. The facilities of TBS also allow for scale modelling such systems in the order of 10:1 to 5:1 scale.

An example of the extent of analysis undertaken by TBS is shown in Train Load-Out Bin Analysis

Wagon Unloading Systems

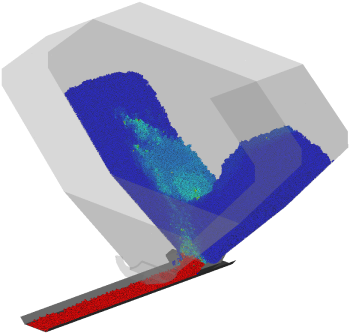

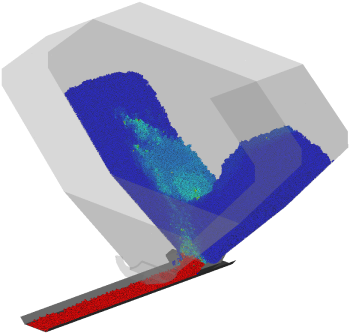

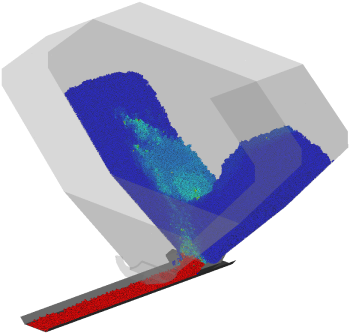

Bottom dump wagons are common for unloading bulk material across ports worldwide. During their design it is critical to consider the material properties being handled. While these wagons typically handle a number of different bulk materials, it is usually only a select few that need to be considered in the design phase. Cohesive arching can occur across the outlet of these wagons, with this being more common in the first bay due to the high consolidation loads during the initial rapid fill of the wagon (from the train load-out on the mine site). If the wagon travels for a long period of time the continual vibration can also cause moisture migration towards the bottom of the wagon which only serves to exacerbate any arching problems. DEM has been used to investigate wagon unloading behaviour, and while it is often not possible to predict cohesive arching it is an excellent tool for analysing unloading patterns, flow rates, wagon door opening sequences, qualitative adhesion of the bulk material (comparative between designs) and the relationship between bulk density and the wagon volume.

Self Unloading Barges

Self unloading barges (SUB’s) are used as part of transhipment services where larger vessels cannot reach the port dock side due to insufficient water depth level or for moving the cargo between different locations.

These systems perform much like typical bin/hopper/feeder configurations, predominanlty in funnel flow, with the added influence of ship motion on the bulk solid cargo handled. The material behaviour within these systems are analysed using both continuum mechanics and DEM. In these applications flow promotion via vibration in parallel with low friction liners is more often than not also incorporated.

-

Services By Industry

Transport Load-Out Systems

TUNRA Bulk Solids (TBS) offers services related to the design of transport load-out systems, including ship, train and truck to ensure reliable and predictable discharge and loading.

Contact our dedicated engineering team for troubleshooting, design audits of new and existing load-out systems and conceptual design expertise.

Train Load-Out Bins

Train load-out (TLO) bins are generally large structures employing flood loading chutes to rapidly fill wagons underneath. When designing such structrues it is important to consider the dynamic loads associated as these can cause significant vibrations. Typically, the calculation of dynamic loads is based on traditional continuum mechanics calculations coupled with site data, however, more recently, with the advancement of computing power, Discrete Element Modelling (DEM) has also been used by TBS in the analyses of these systems. The unloading rate of TLO’s depends on factors such as gate opening time, corresponding outlet size, wagon speed and material properties. The facilities of TBS also allow for scale modelling such systems in the order of 10:1 to 5:1 scale.

An example of the extent of analysis undertaken by TBS is shown in Train Load-Out Bin Analysis

Wagon Unloading Systems

Bottom dump wagons are common for unloading bulk material across ports worldwide. During their design it is critical to consider the material properties being handled. While these wagons typically handle a number of different bulk materials, it is usually only a select few that need to be considered in the design phase. Cohesive arching can occur across the outlet of these wagons, with this being more common in the first bay due to the high consolidation loads during the initial rapid fill of the wagon (from the train load-out on the mine site). If the wagon travels for a long period of time the continual vibration can also cause moisture migration towards the bottom of the wagon which only serves to exacerbate any arching problems. DEM has been used to investigate wagon unloading behaviour, and while it is often not possible to predict cohesive arching it is an excellent tool for analysing unloading patterns, flow rates, wagon door opening sequences, qualitative adhesion of the bulk material (comparative between designs) and the relationship between bulk density and the wagon volume.

Self Unloading Barges

Self unloading barges (SUB’s) are used as part of transhipment services where larger vessels cannot reach the port dock side due to insufficient water depth level or for moving the cargo between different locations.

These systems perform much like typical bin/hopper/feeder configurations, predominanlty in funnel flow, with the added influence of ship motion on the bulk solid cargo handled. The material behaviour within these systems are analysed using both continuum mechanics and DEM. In these applications flow promotion via vibration in parallel with low friction liners is more often than not also incorporated.

-

Services By Material Type

Transport Load-Out Systems

TUNRA Bulk Solids (TBS) offers services related to the design of transport load-out systems, including ship, train and truck to ensure reliable and predictable discharge and loading.

Contact our dedicated engineering team for troubleshooting, design audits of new and existing load-out systems and conceptual design expertise.

Train Load-Out Bins

Train load-out (TLO) bins are generally large structures employing flood loading chutes to rapidly fill wagons underneath. When designing such structrues it is important to consider the dynamic loads associated as these can cause significant vibrations. Typically, the calculation of dynamic loads is based on traditional continuum mechanics calculations coupled with site data, however, more recently, with the advancement of computing power, Discrete Element Modelling (DEM) has also been used by TBS in the analyses of these systems. The unloading rate of TLO’s depends on factors such as gate opening time, corresponding outlet size, wagon speed and material properties. The facilities of TBS also allow for scale modelling such systems in the order of 10:1 to 5:1 scale.

An example of the extent of analysis undertaken by TBS is shown in Train Load-Out Bin Analysis

Wagon Unloading Systems

Bottom dump wagons are common for unloading bulk material across ports worldwide. During their design it is critical to consider the material properties being handled. While these wagons typically handle a number of different bulk materials, it is usually only a select few that need to be considered in the design phase. Cohesive arching can occur across the outlet of these wagons, with this being more common in the first bay due to the high consolidation loads during the initial rapid fill of the wagon (from the train load-out on the mine site). If the wagon travels for a long period of time the continual vibration can also cause moisture migration towards the bottom of the wagon which only serves to exacerbate any arching problems. DEM has been used to investigate wagon unloading behaviour, and while it is often not possible to predict cohesive arching it is an excellent tool for analysing unloading patterns, flow rates, wagon door opening sequences, qualitative adhesion of the bulk material (comparative between designs) and the relationship between bulk density and the wagon volume.

Self Unloading Barges

Self unloading barges (SUB’s) are used as part of transhipment services where larger vessels cannot reach the port dock side due to insufficient water depth level or for moving the cargo between different locations.

These systems perform much like typical bin/hopper/feeder configurations, predominanlty in funnel flow, with the added influence of ship motion on the bulk solid cargo handled. The material behaviour within these systems are analysed using both continuum mechanics and DEM. In these applications flow promotion via vibration in parallel with low friction liners is more often than not also incorporated.