Services List

-

Services By Handling Problems

Feeder Optimisation and Design

Feeders control the gravity flow of bulk solids from storage, such as bins or stockpiles, to provide a uniform feedrate to the receiving belt conveyor.

It is vital that the type of feeder be chosen to suit the bulk material being handled and to provide the range of feed rates required. It is also important that feeders be used in conjunction with mass-flow hoppers to ensure both reliable flow and good control over the feeder loads and drive powers. Correct interfacing of feeders and hoppers is essential if performance objectives such uniform draw of material over the whole of the hopper outlet is to be achieved.

The experienced engineering team at TUNRA Bulk Solids (TBS) offers the following services for feeder optimisation and design:

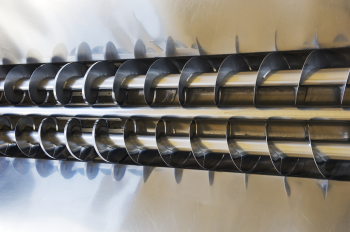

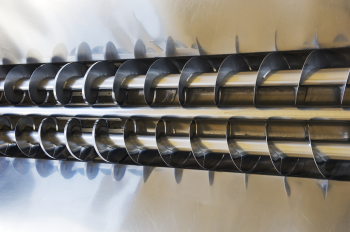

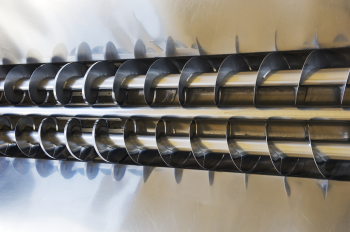

- Screw Feeder Design Advice

- Effective feeder hopper design and choice of wall liners to obtain mass flow

- Optimised feeder interfacing to ensure even draw-down and minimise build-up

- Feeder vertical and pull-out load calculations

- Feeder volume calculations

- Review of existing designs

The following case studies highlight a selection of feeder optimisation and design projects completed by TBS

-

Services By Industry

Feeder Optimisation and Design

Feeders control the gravity flow of bulk solids from storage, such as bins or stockpiles, to provide a uniform feedrate to the receiving belt conveyor.

It is vital that the type of feeder be chosen to suit the bulk material being handled and to provide the range of feed rates required. It is also important that feeders be used in conjunction with mass-flow hoppers to ensure both reliable flow and good control over the feeder loads and drive powers. Correct interfacing of feeders and hoppers is essential if performance objectives such uniform draw of material over the whole of the hopper outlet is to be achieved.

The experienced engineering team at TUNRA Bulk Solids (TBS) offers the following services for feeder optimisation and design:

- Screw Feeder Design Advice

- Effective feeder hopper design and choice of wall liners to obtain mass flow

- Optimised feeder interfacing to ensure even draw-down and minimise build-up

- Feeder vertical and pull-out load calculations

- Feeder volume calculations

- Review of existing designs

The following case studies highlight a selection of feeder optimisation and design projects completed by TBS

-

Services By Material Type

Feeder Optimisation and Design

Feeders control the gravity flow of bulk solids from storage, such as bins or stockpiles, to provide a uniform feedrate to the receiving belt conveyor.

It is vital that the type of feeder be chosen to suit the bulk material being handled and to provide the range of feed rates required. It is also important that feeders be used in conjunction with mass-flow hoppers to ensure both reliable flow and good control over the feeder loads and drive powers. Correct interfacing of feeders and hoppers is essential if performance objectives such uniform draw of material over the whole of the hopper outlet is to be achieved.

The experienced engineering team at TUNRA Bulk Solids (TBS) offers the following services for feeder optimisation and design:

- Screw Feeder Design Advice

- Effective feeder hopper design and choice of wall liners to obtain mass flow

- Optimised feeder interfacing to ensure even draw-down and minimise build-up

- Feeder vertical and pull-out load calculations

- Feeder volume calculations

- Review of existing designs

The following case studies highlight a selection of feeder optimisation and design projects completed by TBS