Services List

-

Services By Handling Problems

DEM and Calibration Services

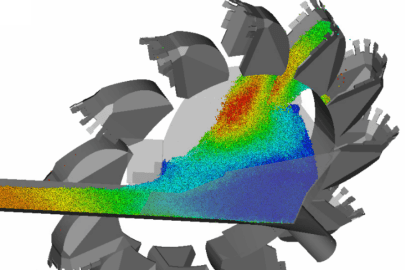

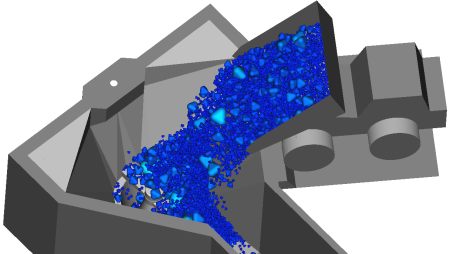

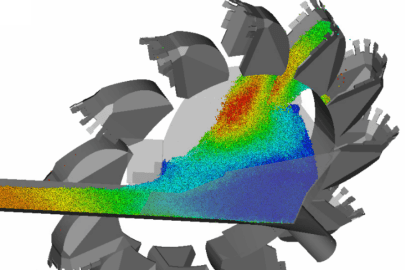

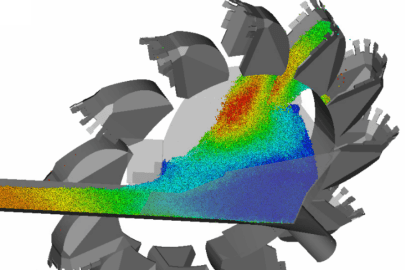

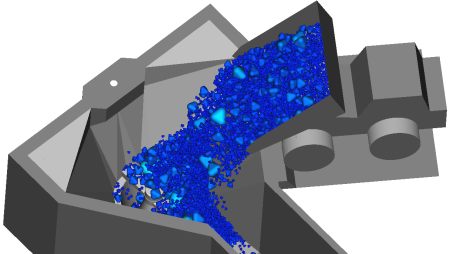

Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk material processing and handling operations.

TUNRA Bulk Solids (TBS) provides various services applying DEM ranging from troubleshooting, design audits and concept design to fundemental research and contact model development.

The TBS DEM methodology incorporates a first-principle continuum approach to ensure correct simulation outputs.

Typical outputs of DEM analyses include, but are not limit to:

- General flow observations

- Expected material trajectories

- Quantitative prediction of velocity profiles

- Qualitative prediction of chute liner wear

- Centralised loading of receiving conveyor belts

- Qualitative estimation and evaluation of belt wear

- Hopper/feeder interface design

- Adhesion/build-up of bulk materials on equipment surfaces

- Particle degradation

Additional competencies are available for coupling of DEM with Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) to investigate specific problems such as passive dust control in transfer chutes or the interaction between bulk materials and materials handling equipment.

Examples of typical projects involving DEM include:

- Transfer chutes (from simple one-to-one transfers to complex, multi-bifurcated systems)

- Hoppers and Feeders

- Train loading and unloading operations

The following case studies highlight a selection of projects completed by TBS using DEM analysis:

- Conceptual design of double spoon transfer chute

- Re-design of grain ship loading chute

- Design of slewing and luffing stacker transfer chute

- Redesign of a nickel ore hopper

- Optimisation of belt wear and tracking on coal reclaimer

- Predicting and optimising fertiliser dispersion patterns

- DEM analysis of silo eccentric flow loads

Calibration of Bulk Material Parameters for DEM

To obtain realistic simulation results and accurate characterisation of the material properties used in DEM is essential.

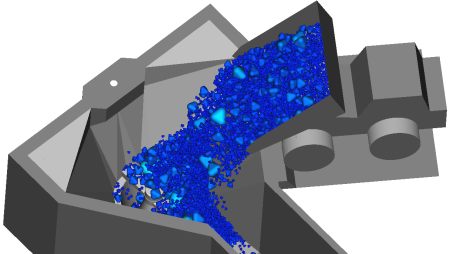

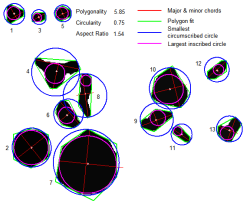

TBS offers calibration services for DEM simulation parameters. In addition to standard flow property tests, a set of physical bench-top tests can be conducted on bulk material samples provided by customers, including the determination of:

- Angle of repose

- Inclining wall friction – single particles/consolidated bed

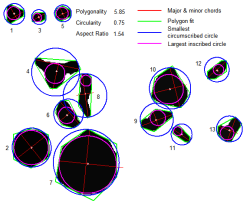

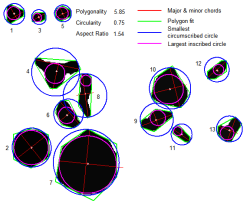

- Particle shape characterisation

- Rock-box flow testing

- Chute liner adhesion testing

- Particle Degradation

-

Services By Industry

DEM and Calibration Services

Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk material processing and handling operations.

TUNRA Bulk Solids (TBS) provides various services applying DEM ranging from troubleshooting, design audits and concept design to fundemental research and contact model development.

The TBS DEM methodology incorporates a first-principle continuum approach to ensure correct simulation outputs.

Typical outputs of DEM analyses include, but are not limit to:

- General flow observations

- Expected material trajectories

- Quantitative prediction of velocity profiles

- Qualitative prediction of chute liner wear

- Centralised loading of receiving conveyor belts

- Qualitative estimation and evaluation of belt wear

- Hopper/feeder interface design

- Adhesion/build-up of bulk materials on equipment surfaces

- Particle degradation

Additional competencies are available for coupling of DEM with Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) to investigate specific problems such as passive dust control in transfer chutes or the interaction between bulk materials and materials handling equipment.

Examples of typical projects involving DEM include:

- Transfer chutes (from simple one-to-one transfers to complex, multi-bifurcated systems)

- Hoppers and Feeders

- Train loading and unloading operations

The following case studies highlight a selection of projects completed by TBS using DEM analysis:

- Conceptual design of double spoon transfer chute

- Re-design of grain ship loading chute

- Design of slewing and luffing stacker transfer chute

- Redesign of a nickel ore hopper

- Optimisation of belt wear and tracking on coal reclaimer

- Predicting and optimising fertiliser dispersion patterns

- DEM analysis of silo eccentric flow loads

Calibration of Bulk Material Parameters for DEM

To obtain realistic simulation results and accurate characterisation of the material properties used in DEM is essential.

TBS offers calibration services for DEM simulation parameters. In addition to standard flow property tests, a set of physical bench-top tests can be conducted on bulk material samples provided by customers, including the determination of:

- Angle of repose

- Inclining wall friction – single particles/consolidated bed

- Particle shape characterisation

- Rock-box flow testing

- Chute liner adhesion testing

- Particle Degradation

-

Services By Material Type

DEM and Calibration Services

Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk material processing and handling operations.

TUNRA Bulk Solids (TBS) provides various services applying DEM ranging from troubleshooting, design audits and concept design to fundemental research and contact model development.

The TBS DEM methodology incorporates a first-principle continuum approach to ensure correct simulation outputs.

Typical outputs of DEM analyses include, but are not limit to:

- General flow observations

- Expected material trajectories

- Quantitative prediction of velocity profiles

- Qualitative prediction of chute liner wear

- Centralised loading of receiving conveyor belts

- Qualitative estimation and evaluation of belt wear

- Hopper/feeder interface design

- Adhesion/build-up of bulk materials on equipment surfaces

- Particle degradation

Additional competencies are available for coupling of DEM with Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) to investigate specific problems such as passive dust control in transfer chutes or the interaction between bulk materials and materials handling equipment.

Examples of typical projects involving DEM include:

- Transfer chutes (from simple one-to-one transfers to complex, multi-bifurcated systems)

- Hoppers and Feeders

- Train loading and unloading operations

The following case studies highlight a selection of projects completed by TBS using DEM analysis:

- Conceptual design of double spoon transfer chute

- Re-design of grain ship loading chute

- Design of slewing and luffing stacker transfer chute

- Redesign of a nickel ore hopper

- Optimisation of belt wear and tracking on coal reclaimer

- Predicting and optimising fertiliser dispersion patterns

- DEM analysis of silo eccentric flow loads

Calibration of Bulk Material Parameters for DEM

To obtain realistic simulation results and accurate characterisation of the material properties used in DEM is essential.

TBS offers calibration services for DEM simulation parameters. In addition to standard flow property tests, a set of physical bench-top tests can be conducted on bulk material samples provided by customers, including the determination of:

- Angle of repose

- Inclining wall friction – single particles/consolidated bed

- Particle shape characterisation

- Rock-box flow testing

- Chute liner adhesion testing

- Particle Degradation