Case Studies

Grain Ship Loading Chute

Project Scope

Bulk material: Grain – wheat and barley

Equipment: Telescopic ship loading spout/chute

Challenge: High dust levels and non-standard operating procedure

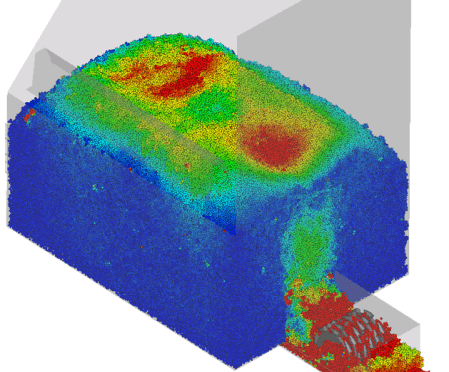

Upgrade of Gravity Reclaim Stockpile

Project scope

Bulk material: Iron ore fines

Equipment: 42,000 cubic metre conical stockpile with two reclaim hoppers for train loading

Challenge: Insufficient live capacity due to rathole formation above reclaim hoppers

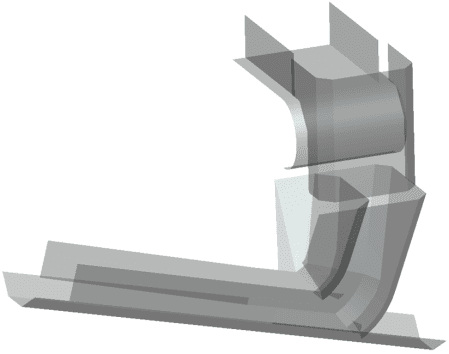

Design of Slewing and Luffing Stacker Transfer

Project scope

Bulk material: Coal

Equipment: Central transfer on a slewing/luffing stacker operating at 8000t/h and speeds over 5.6m/s

Challenge: Development of a favourable concept design in view of tight structural constraints

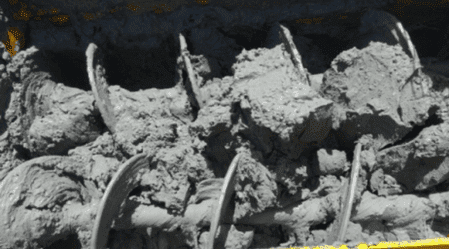

Redesign of Road Receiving Hoppper

Project scope

Bulk material: Nickel ore

Equipment: Road receival hopper

Challenge: Arching and ratholing due to difficult nature of material resulting in blockage and downtime

Discharge System for Aluminium Hydrate

Project scope

Bulk material: Aluminium hydrate, known to be a very abrasive material

Equipment: Existing metering valve used to discharge alumina into a pneumatic conveying system at a rate of 1 to 20 t/h. The valve operates via a conical plug moving up or down, thus changing the annular opening size and controlling the material discharge.

Challenge: Feeding into the conveying system is unreliable, leading to process interruptions. This problem has existed for 20 years.

Optimisation of Reclaimer Belt Wear and Tracking

Project scope

Bulk material: Coal

Equipment: Reclaiming system with bifurcated surge bin feeding yard belt conveyor via two belt feeders

Challenge: Belt wear and tracking issues required replacement of the feeder belts after only 12 months of service

Double Spoon Transfer Design

Project Scope

Bulk material: Potash

Equipment: Chute at the end of long, fast-moving feeder operating at 6000t/h

Challenge: Limited head height, wide and slow-moving stream, steep outgoing belt inclination

Recovery and Pumping of Marine Sediment

Project Scope

Bulk material: Marine sediments

Equipment: Twin screw feeder, twin screw mixer, swing tube cylinder positive displacement pump and 100 meters of 1.6 MPa 90mm plastic pipe

Challenge: Recovering and pumping marine sediment to a shore landfill

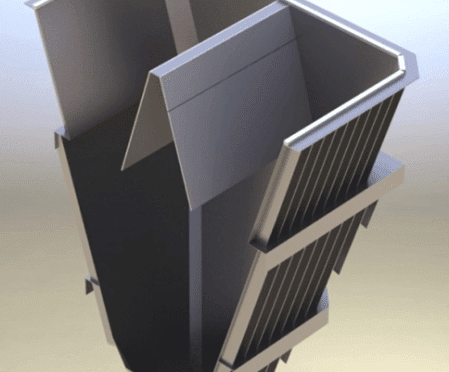

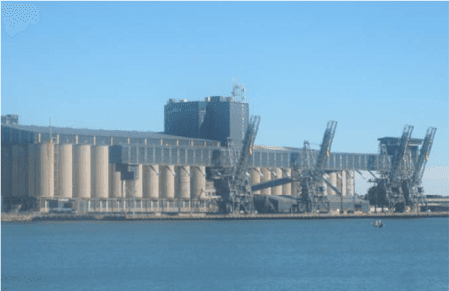

Passive Dust Control in Ship Loading Chutes

Project Scope

Bulk material: Grain (wheat, durum, barley)

Equipment: Telescopic ship loading spout/chute

Challenge: High dust levels during loading and limited reach leading to increased loading time

Surge Bin Design for Consistent Slurry Density

Project Scope

Bulk Material: Mineral Sand

Equipment: Surge Bin

Challenge: Inconsistent slurry density at discharge, slumping and blockages

Global Belt Tender Project

Project Scope

Equipment: Belt Conveyor Systems

Challenge: Comparative testing of conveyor belt samples from a range of belt suppliers for a global tender project

DEM Analysis of Silo Eccentric Flow Loads

Project Scope

Bulk Solid Material: Coal

Equipment: Storage Silo

Challenge: Cracks on Silo Wall

Aim: Analysis of Silo Asymmetry Normal Pressures due to Eccentric Discharge using DEM Simulation.

Train Load-Out Bin

Project Scope

Bulk Solid Material: Iron Ore

Equipment: Train Load-out Bin (TLO)

Challenge: TLO dynamic load analysis based on TUNRA analytical approach and Discrete Element Method (DEM) modelling

Hopper Feeder Interface

Project Scope

Bulk Solid Material: Coal

Equipment: Chain Conveyor, Hopper

Challenge: Ratholing, denting and buckling of bunker walls

Silo Quaking Analysis on Coal Bins

Project Scope

Bulk Solid Material: Coal

Equipment: Concrete Coal Silo

Challenge: Severe silo quaking problems in reinforced concrete coal silos

Silo Quaking Analysis on Wheat Conditioning Silo

Project Scope

Bulk Solid Material: Wheat

Equipment: Wheat Conditioning Silo

Challenge: Silo quaking problems experienced in a 200 tonne wheat conditioning silo

Energy Efficiency Review of a Belt Conveying System

Project Scope

Equipment: Belt Conveyor System

Challenges : To identify differences in material characteristics between the bottom covers of the belts and determine how these differences affect the energy requirements of the belt conveying system.

Using Larger Rollers to Improve Energy Efficiency in Belt Conveyor Systems

Project Scope

Equipment: Idler Rollers for Long Distance Belt Conveyor Applications

Objective: TUNRA Bulk Solids, in collaboration with Big RollerTM and ContiTech Australia, assesses the influence of larger diameter idler rollers on energy savings for overland belt conveying systems.

DEM Analysis on Hopper Wall Loads during Eccentric Discharge

Project Scope

Equipment: Hoppers

Problem: Understanding how wall loads are affected by eccentric discharge in bin and hopper design.